Gum Arabic: The Ultimate Guide to Its Production, Benefits, and Uses

Gum Arabic

The production of Gum Arabic involves several carefully controlled stages to ensure the highest quality and purity.

Gum Arabic: The Ultimate Guide to Its Production, Benefits, and Uses

Gum Arabic

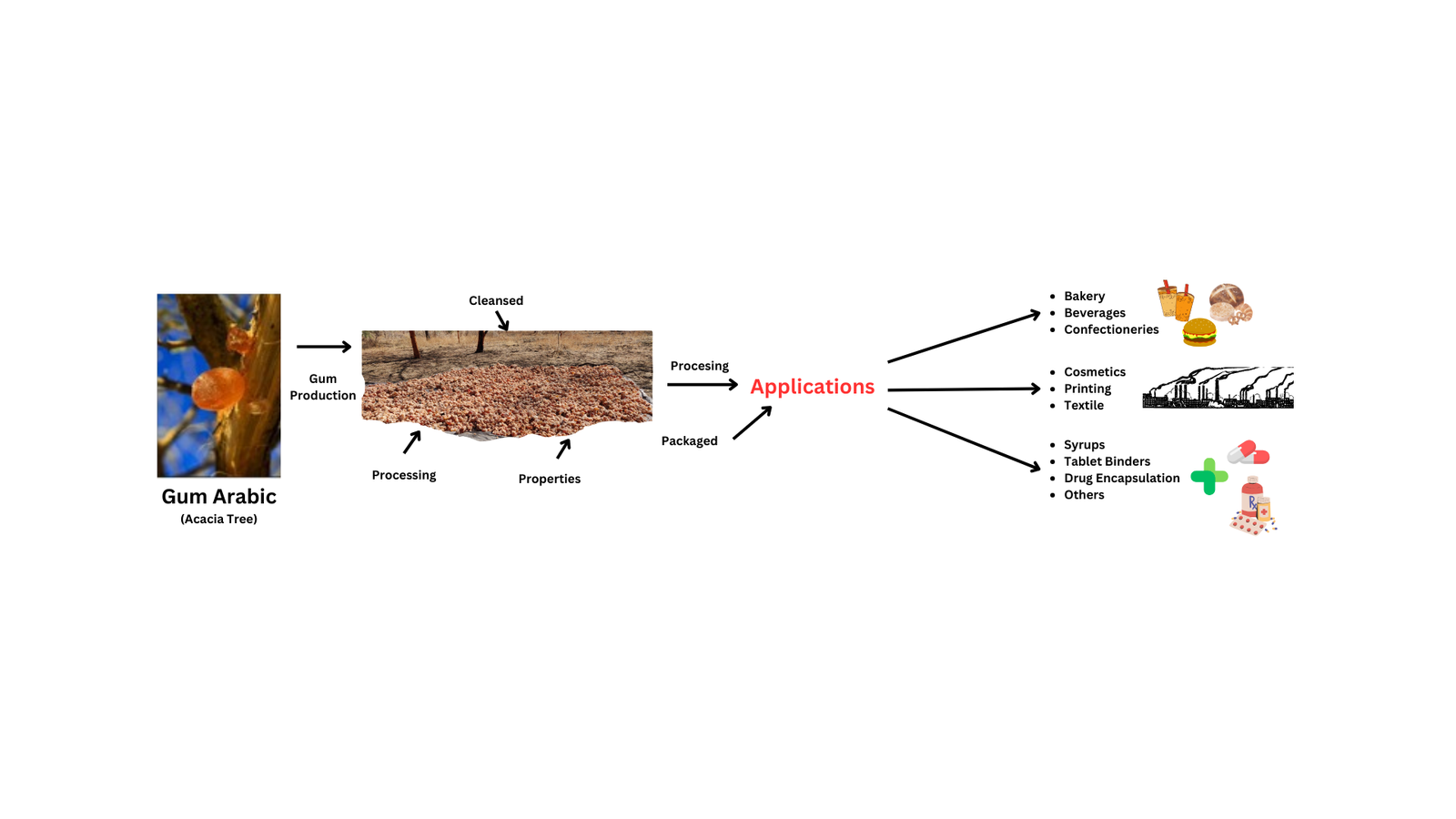

A natural exudate from the Acacia tree, has been a valuable ingredient in various industries for centuries. From food and beverages to pharmaceuticals and cosmetics, its versatility makes it a highly sought-after product. The production of Gum Arabic involves several carefully controlled stages to ensure the highest quality and purity.

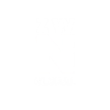

Gum produced from the Acacia Senegal tree or Acacia Seyal tree, known as gum arabic (GA), is the oldest and most well-known exudate gum commercially used for more than 5000 years. Some species of the Acacia genus are the source of GA. Due to its natural origin and safety record, it is recognized as the most crucial exudate gum. It finds application in food, pharmaceuticals, cosmetics, textile, paper, ink, adhesive, paint and printing. It is mainly produced in sub-Saharan Africa and small quantities in Arabian Peninsula and South Asia. GA is primarily consumed in developing and developed countries. The annual average export of crude and semi-processed gum was about 35,000 tons in 1992–94, which increased to 102,000 tons during 2014–16. During this period, processed gum exports increased from 17,000 tons to 53,000 tons. The value of GA export during 2014–16 was an average of $337 million per year, in which the contribution of crude gum and semi-processed gums were 44 & 56%, respectively.

Acacia senegal is a hardy tree that can survive in dry, subtropical, and semi-arid regions. It is a small, spiny shrub that usually grows between 2 to 6 meters tall, though it can reach up to 12 meters. The tree has many branches that split repeatedly, forming a rounded, flat-topped shape when fully grown. Its trunk is about 30 cm wide and covered in greyish-white bark. The tree’s leaves are small, green-grey, and 3.5–8 cm long, with tiny leaflets that are either blunt or slightly pointed. It also has two small glands on the leaves. The flowers grow in clusters on long, cylindrical spikes and are yellowish-white with a pleasant fragrance. When the tree produces seed pods, they are thin, flat, and oblong, starting off green before maturing. A key feature of Acacia senegal is its strong, hooked thorns, which grow in groups of three just below the leaf nodes. One thorn points forward, while the other two curve backward, making the tree well-protected from herbivores

Acacia senegal is found abundantly in sub-Sahara African countries, i.e. Mauritania, Mali and Senegal in the west; Burkina Faso, Niger, Benin, Nigeria, Chad and Cameroon in the northern central region; Sudan, Somalia, Eritrea and Ethiopia in the East; and Angola, Mozambique, Zimbabwe, Botswana, Namibia, and South Africa in the West. Apart from Africa, Acacia senegal is also found in Pakistan (Sindh and Baluchistan), Oman and India (Rajasthan, Haryana, Gujrat, MP, UP and Punjab)

The Making of Gum Arabic: From Tree to Final Product

Tapping, Incision and Cleansing

The process begins with tapping Acacia trees, primarily found in Africa’s Sahel region, including Sudan, Chad, and Nigeria. Farmers make small incisions in the tree bark, allowing the gum to naturally ooze out and harden into resinous nodules. These nodules are then carefully collected by hand, ensuring minimal impact on the tree’s health.

Once harvested, the raw Gum Arabic is sorted to remove impurities such as tree bark, sand, and other debris. It is then washed and dried under controlled conditions to preserve its natural properties. This step is crucial in maintaining the purity and uniformity of the final product.

The cleaned gum is transported to processing facilities, where it undergoes further refinement. It is broken down into smaller granules and dissolved in water to create a liquid solution. Filtration ensures the removal of any remaining impurities, improving clarity and consistency.

For industrial applications, particularly in food and pharmaceuticals, the gum is transformed into a fine powder using spray-drying technology. This method enhances solubility, improves storage stability, and ensures uniform quality across batches. The result is a highly functional ingredient that retains all its natural benefits.

Regulatory Compliance

Before distribution, rigorous quality control testing is conducted to meet industry standards and regulatory requirements, including FDA approval and GRAS certification (FDA Source). Additionally, Gum Arabic has been recognized as a dietary fiber by the FDA, supporting its role in promoting digestive health and metabolic function (FDA Dietary Fiber Update).

Recent research also highlights the industrial applications and quality enhancements of Gum Arabic, making it a critical ingredient in multiple sectors (Industrial Crops and Products). Furthermore, its use as an emulsifier and stabilizer in various food products is regulated under FDA regulations (FDA Emulsifier Regulations). Once approved, the final product is carefully packaged in moisture-resistant containers to maintain its integrity and extend shelf life.

ZWN Global is dedicated to sustainable and ethical sourcing, ensuring fair compensation for farmers and minimizing environmental impact. By investing in responsible harvesting and innovative processing techniques, we provide a product that is both effective and environmentally friendly.

Discover More About US

The journey of Gum Arabic from Acacia tree to finished product is a meticulous process requiring careful harvesting, purification, and advanced processing techniques. With our commitment to quality and sustainability, we continue to supply high-grade Gum Arabic that meets the diverse needs of industries worldwide. Contact us today to learn more about our premium Spray-Dried Gum Arabic solutions.